A C Whalan & Co Steel Shouldered Piping system pipe is manufactured by accredited and approved ISO 9001 Mills from certificate strip to our grade and specification. The ERW seam welds are 100% Eddy Current tested during manufacture, with the welding of the Shouldered End conducted in accordance to Australian Standards. Galvanizing is completed post end welding in accordance to AS/NZS 4680. Testing of the Shouldered product is conducted by NATA approved facilities. Hydrostatic & tensile testing is conducted in accordance to AS 4037 and AS 1391

Manufactured in ISO 9001 accredited Mill from Mill Test Certified strip.

Manufactured in ISO 9001 accredited Mill from Mill Test Certified strip.

Hot Dipped Galvanised to AS:4680

ERW (Electric Resistance Welded)

Standard lengths 6 metre or 6.5 metre

Other sizes available upon request

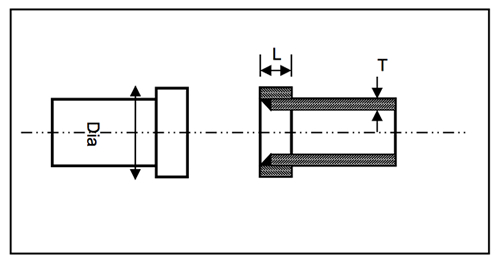

| Pipe | Pipe | Wall Thickness "T" |

Shoulder |

|||

| N.B. |

O.D. |

|||||

| "DS" "L" | ||||||

| 50 mm | 60.3 mm | 2.0 mm | 66.5mm | 16 mm | ||

| 80 mm | 88.9 mm | 2.0 mm | 97mm | 16 mm | ||

| 100 mm | 114.3 mm | 2.0 mm | 122mm | 17.5 mm | ||

| 150 mm | 165.1 mm | 2.5 mm | 174.5mm | 17.5 mm | ||

| 200 mm | 219.1 mm | 3.2 mm | 232mm | 20.5 mm | ||

| 200 mm | 219.1 mm | 4.4 mm | 232mm | 20.5 mm | ||